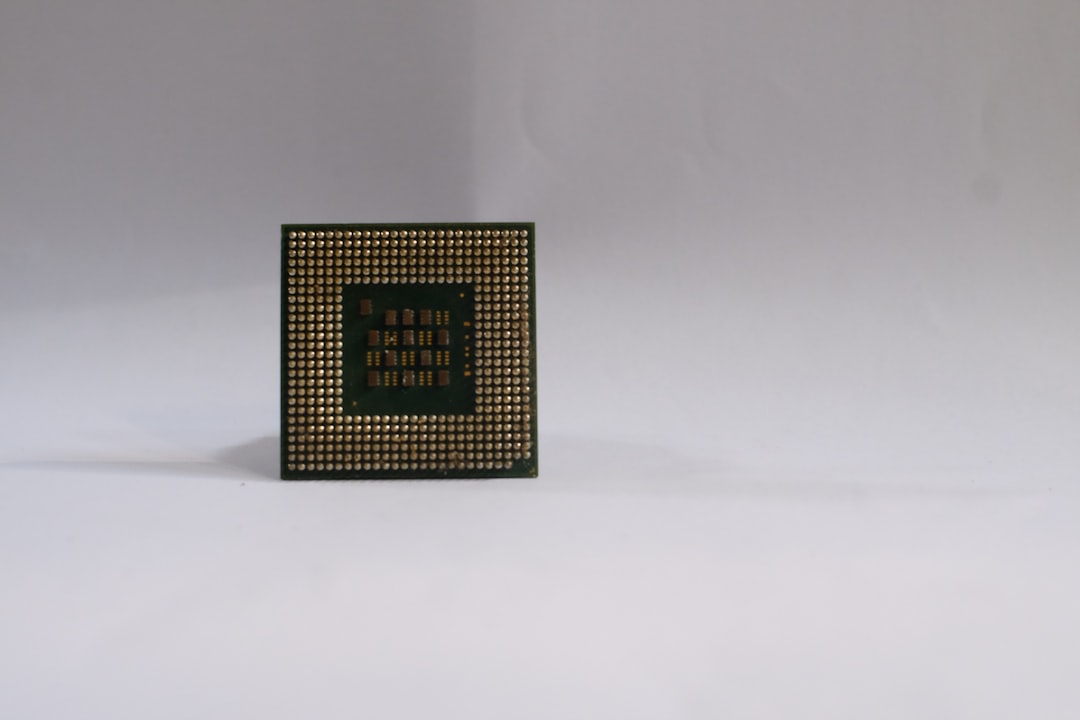

The performance and longevity of a central processing unit (CPU) rely heavily on thermal management. One of the most integral yet often overlooked components aiding in this aspect is the Integrated Heat Spreader (IHS). Positioned as a flat metal lid on top of a CPU die, the IHS plays a crucial role in protecting the delicate silicon core while enhancing the efficiency of heat transfer from the processor to a cooling solution.

In modern hardware culture, many enthusiasts focus on the cooler, thermal paste, and airflow, but the IHS quietly does its job underneath it all. This article explores the function, construction, benefits, and design considerations of the IHS, shedding light on why it’s far more than just a metal cover.

What Is an Integrated Heat Spreader?

The Integrated Heat Spreader is a conductive metal lid permanently attached to the top layer of the processor. It serves as the physical interface between the CPU die (the chip’s core) and the cooling mechanism, such as a heatsink or liquid cooler cold plate.

Its main function is to spread the concentrated heat from the CPU die over a larger surface area, allowing for better contact and dissipation through the cooler. A typical IHS is made of materials such as copper and nickel-plated for corrosion resistance and improved thermal conductivity.

Why the IHS Matters: Role in Thermal Management

The tiny silicon die found inside a CPU produces a significant amount of heat during operation. Because of its small size, the heat is incredibly concentrated. Without an intermediary component like the IHS, this heat would damage the die and reduce the CPU’s lifespan and efficiency.

This is where the IHS comes into play:

- Heat Distribution: It acts as a thermal buffer, distributing heat more evenly before it’s transferred to the cooling hardware.

- Structural Protection: The IHS protects the core from physical damage during heat sink or cooler installation (especially under heavy pressure).

- Improved Cooling Interface: A flat IHS ensures direct and consistent contact with the cooler, enabling effective heat transfer away from the processor.

Materials and Design

Generally, the IHS base is constructed from copper because of its excellent thermal conductivity. To prevent oxidation and improve durability, it is then coated with a thin layer of nickel. This combination strikes a balance between heat performance and physical resilience.

The shape and flatness of the IHS are also critical design factors. A poorly manufactured IHS with uneven surfaces—referred to as “bowed” or “warped”—can hinder the performance of the cooling system by creating air gaps that impede thermal transfer.

Delidding: Exposing the Truth Beneath

Among hardware enthusiasts and overclockers, the concept of delidding—removing the IHS—has gained popularity. Many believe that factory-installed thermal interface materials (TIM) used between the die and the IHS are subpar, limiting heat transfer efficiency. By delidding, users can replace this TIM with high-performance liquid metal compounds and then reseal the IHS for improved results.

While delidding may improve temperatures by up to 10–20°C in some cases, it comes with significant risk:

- Permanent damage to the CPU die during removal

- Voiding of warranty

- Need for precision resealing and TIM reapplication

Nevertheless, this process highlights how crucial the IHS is — not just in its structural integrity, but also in the quality of the materials working under the surface.

Manufacturing and Soldering vs. TIM

Not all CPUs are created equal in terms of IHS design. High-end or enthusiast-grade CPUs sometimes come with a soldered IHS. In this case, a solder material (usually a special metallic compound) is used instead of thermal paste between the die and IHS.

A soldered IHS provides significantly better thermal transfer compared to traditional thermal interface materials. However, it is also harder and less forgiving if the processor overheats, as the metal compound can become brittle or degrade over time.

Typical Thermal Design Paths:

- Soldered IHS on CPU core: Ideal for high-end chips needing consistent heat dissipation

- Non-soldered IHS using paste: Common in mid-range and entry-level CPUs

- Direct-die cooling (no IHS): Rare and used in custom or experimental cooling setups

Each approach presents trade-offs between safety, performance, and manufacturing cost.

Innovations and Trends in IHS Design

With the rise of multi-core and high-performance computing tasks—like gaming, rendering, and AI workloads—the thermal demands on CPUs have dramatically increased. Manufacturers are responding with advanced IHS designs, including:

- Thicker copper layers for enhanced thermal conductivity

- Differential height IHS to accommodate chiplet architecture (multiple dies inside a single processor)

- Use of exotic interface materials like liquid metal composites in ultra-high-end CPUs

These innovations aim to push the envelope of performance while ensuring that CPUs remain thermally stable even under heavy load conditions.

Conclusion

The Integrated Heat Spreader may appear to be a simple metal covering, but its role in thermal dynamics and CPU protection is vital. As processors continue to become more powerful and compact, the importance of effective heat dissipation grows in tandem. The IHS stands as a critical piece in the larger puzzle of computer hardware design—safeguarding the silicon brain of your system while ensuring it maintains peak performance.

FAQ: CPU Integrated Heat Spreader (IHS)

- Q: Can I remove the IHS from my CPU?

A: Yes, this is called “delidding,” but it is risky and can damage the CPU. It also voids any manufacturer warranty. - Q: Is the IHS responsible for cooling the CPU?

A: Not directly. The IHS helps transfer heat from the die to the cooler, improving the efficiency of the overall cooling system. - Q: What material is the IHS made of?

A: Most IHS components are made of copper for thermal performance and coated with nickel for durability and oxidation protection. - Q: Why do some CPUs run cooler than others?

A: Factors include the type of cooling system used, the quality of the thermal interface material, the design of the IHS, and whether the IHS is soldered or uses standard TIM. - Q: Are all CPUs soldered under the IHS?

A: No. Some CPUs use thermal interface paste between the die and IHS, while others use solder for better thermal conductivity.